ICG full-automatic blowback filter, Shanghai Weixiu

Filtering Equipment Co., Ltd Telephone: 021-50117775

The full-automatic blowback filter is applicable to filtering and

cleaning of high viscosity and hazardous liquids.

Application Scope

The full-automatic blowback filters are used for filtering high

viscosity and hazardous liquids, such as polymers and monomers, resin,

paintings, printing inks, adhesives, lubricants, coolants and cutting fluids.

Successful Applications of the Full-automatic Blowback

Filter

Inks, paintings, plastic, collosol, dyes, pigments, latex,

polymers, adhesives, latex paintings, coolants, solvent acrylic enamel, calcium

carbonate, brine, corn syrup, tea extracts, glucopyrose galactopyranoside,

cooking oil, glucose, lard, chocolate, peanut butter, drinks, toothpaste,

shampoo, lubricants, clay mud, fuel oil, sulfuric acid, muriatic acid and

ethylene glycol.

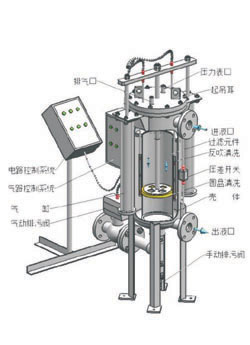

Structure and Working Principles of the ICG Filter

The ICG filter features full-automatic continuous filtering and

applies the disc cleaning system that is driven by dual-cylinder. The filter

uses a cleaning disc that has a spring to clean collected residues through

reciprocating movement in the filtering element. The filtrate is filtered from

the inside to the outside of the filtering element. Residues are retained on the

surface of the filtering element and thus can be easily cleaned and collected in

the collecting chamber. In the downward stroke of the filter, all residues are

collected in the collecting chamber by the cleaning disc. In the upward stroke

of the filter, the cleaning disc cleans the residues on the surface of the

filtering element. Then liquids flush the residues to pass through the disc and

enter the collecting chamber. Meanwhile, to effectively eliminate soli d

particles in the liquids, in addition to the disc cleaning function, the ICG

filter applies the compressed air blowback cleaning function to ensure that

impurities are eliminated and the filter screen is thoroughly cleaned.

Design Features of the ICG Filter

The filter applies full-automatic continuous filtering, meeting

automatic operation requirements;

The filter is driven by compressed air and thus is safe and

explosion resistant.

The filter applies mechanical cleaning for the filter screen and

thus features long service life, high filtering precision and excellent

corrosion resistance.

The filter reduces the risk that operators contact hazardous

matters, reduces environmental pollution and reduces requirements on labor. In

addition, the filter screen does not be replaced.

The filter increases the profit margin, increases the overall

efficiency and shortens the shutdown repairing time.

The filter is compactly designed and covers small area.

The filer does not need to be stopped during collection and

discharging residues.

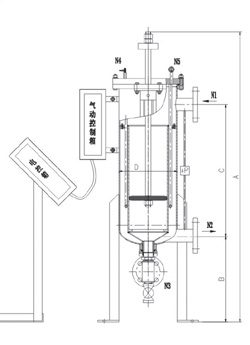

Model | A (mm) | B (mm) | C (mm) | D (mm) | Size of inlet/outlet (mm) | Size of discharging outlet (mm) | Reference flow (m3/h) |

WX-ICG273 | 1750 | 400 | 620 | 273 | 50 | 40 | 40 |

WX-ICG219 | 1740 | 390 | 620 | 219 | 40 | 40 | 30 |

排气口 | Air outlet | 压力表口 | Pressure gauge interface |

电气控制 | Electrical control | 压差开关 | Pressure difference switch |

出液口 | Discharging outlet | 起吊耳 | Hanging hole |

手动排污阀 | Manual blow-off valve | 气动排污阀 | Hydraulic blow-off valve |

进液口 | Liquid inlet | 气动控制 | Hydraulic control |

壳体 | Shell | 气动控制箱 | Hydraulic control box |

过滤元件 | Filtering element | 电控箱 | Electric control box |

反吹清洗 | Blowback cleaning | 汽缸 | Cylinder |

圆盘清洗 | Disc cleaning |

|

|