Side-in bag filter, Shanghai Weixiu Filtering Equipment Co., Ltd Telephone: 021-50117775

Side-in bag filters apply the side-in and bottom-out method. Liquids to be filtered are pushed or suctioned by pressure in the pipe to the filtered. Liquids to be filtered are filtered by the filtering bag supported by the filter basket to ideally separate solid and liquid and thus achieve the filtering effect. Different filtering precision depends on the precision of the filtering bag.

Liquids flow into the filter through the filtering bag; thus, liquids are distributed evenly on the filtering surface in the filtering bag and constantly in the whole layer with low affect by turbulent flow and excellent filtering effect.

Side-in bag filters features proper structure, good tightness, strong negotiability and simple operation. In particular, side leakage rarely occurs in filtering bag to ensure filtering precision and easy filtering bag replacement, reducing operation cost. The outer and inner surfaces of the bag filter are mechanically sandblasted and thus even and easy for cleaning. The filter can also be customized to provide heat preserving function, adjustable supporting stand or hangers to meet different requirements.

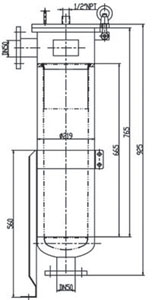

Model: | A | B(mm) | C(mm) | D(mm) | E(mm) | Maximum flow (m3/h) | Inlet/outlet size |

|

Max. | Min. |

|

|

|

|

|

|

|

WX-1C | 740 | 630 | 471 | 550 | 412 | 180 | 20 | DN50 |

WX-2C | 1140 | 990 | 831 | 910 | 772 | 180 | 45 | DN50 |

Design Features of the Side-in Bag Filter

The filter is precisely made and features high precision, fewer seams, stable pressure and easy operation.

The filter applies typical sealing structure design. Specially designed heat-melting filtering bad (steel ring or plastic ring) to prevent leakage of the filter and the filtering process.

The filter is easy for installation and operation and covers small area. It is widely used for rough filtering, moderate filtering and fine filtering.

With proper and compact pipe connection and polished filtering baskets, no impurities accumulate in the filter and pipes and thus the filter can achieve high filtering efficiency and needs minimum operation space.

Stainless steel hanger bolt components can be used to replace common galvanized carbon steel components for the locking device to prevent rust of the bolts after years of operation.

Compared with frame filter, strainer core filter, raw water pre-filter and fine filter under the same filtering effect, the side-in bag filter advantages in low investment, long service life and low filtering cost.

Under the same structure, operation cost, filtering effect and processing capacity, it advantages in high performance price ration.